Last week, I found out one of my most influential friends in Gunnison, Les, is moving away. Although he told me the news while simultaneously smirking about how good the bird hunting near his new home is, that didn’t stop a hard pit of sadness from tightening in my gut. At least he’s relocating to one of my top three favorite places in the lower 48. Admittedly, I am anxious to visit him. But I will sorely miss his form corrections during archery club shoots, gentle way of talking about the world, and generous sharing of his leather working skills.

Les used to make saddles. He’s won awards for his craftsmanship and artistry. He learned the trade from prominent saddlemakers in California. Dan’s actually riding in one of his saddles right now, and I must say, it’s freaking gorgeous. I’ll post some photos of it.

Anyways, after I expressed a need for chinks, he gave me the pair he built for his son when he was 12. The stiff leather looked untouched, as if it’d never been worn while horseback; I don’t think his son ever used them. He cut me a new belt (the original was too tight for my hips), instructed me while I hammered a pattern into it, and watched silently as I carved my initials. Along with the new custom-fit chinks, he sent me home with tooling equipment and leather scraps of the highest quality in case I wanted to keep up my practice.

After riding in them for two and a half years now, those chinks aren’t so stiff anymore. I can’t believe I let that much time pass between my two leatherworking lessons.

Two weeks ago, I texted him asking if I could drop off some donations to the archery club at his house. As I set the two vintage bows down by his garage, he burst through the backyard’s gate and joked that I was bribing him.

“Are you trying to become the new club president?”

“Huh? Why does it need a new president?”

“I’m moving to Wyoming.”

“I’d better hurry up and schedule that stitching lesson then!”

It was decided. Dan’s broken chinks would be my first stitching project.

Stitching animal hide is different than sewing fabric.

To stitch leather, one needs:

Poly thread size 277

Beeswax

Angled awl

Compass

Dull-tipped needles with a huge eyelet

Stitch mar or wheel

Tacky gardening gloves

Barge’s contact cement

Hard rubber or leather mat for awling on

Good leather

Here’s what I understand after my first lesson.

First, glue your leather pieces together with the Barge’s cement. Don’t glue where you plan on stitching so you don’t have to awl and stitch through the glue in addition to the leather. Wait to stick the leather together until the glue is tacky. Les said it may look dry, but it’s not. Don’t touch it, just stick it together.

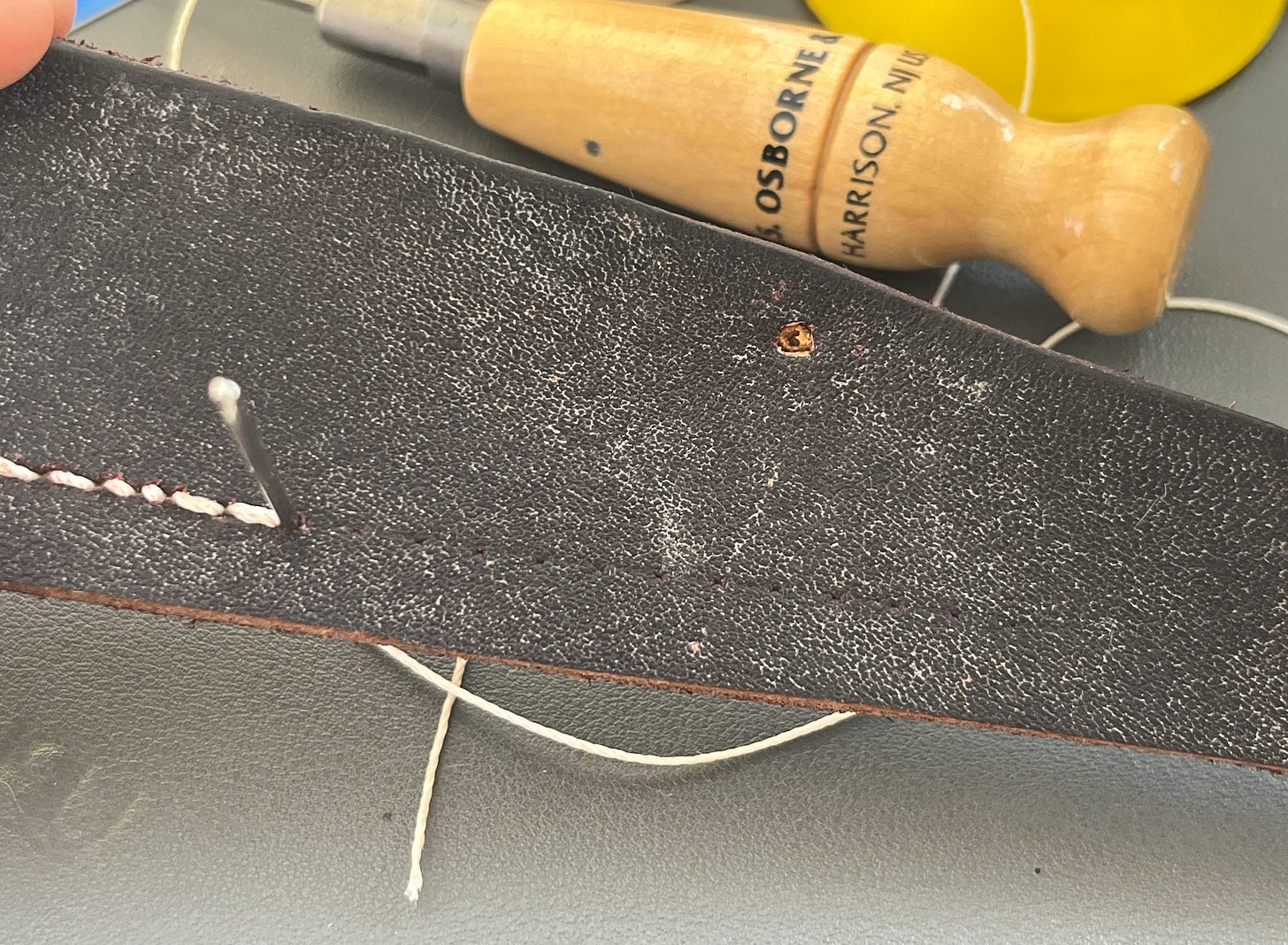

Then, use the compass to draw a line where you’d like to stitch. Using a stitch mar with a 6 stitches per inch wheel on it, go down your line. Next, go down the mar’s marks with your awl, being sure to go in at an angle and poke through both leather layers. Awl six or so stitches at a time.

To set up your needles, first, cut a length of thread. Run the thread over a block of beeswax to increase its durability and stickiness. Then, thread both ends of it through a needle. You need a needle on both ends of the thread.

Poke a needle through the first hole and pull the string halfway through. Then, go through the next hole with the needle on the front side of the leather. Do the same with the needle on the backside, and continue in this figure 8 style until you finish the project or run out of string.

If you run out of string or you want to tie off an end, loop the outside needle back into the previous hole. Cut it short, and use a lighter to burn the end. Smash the melted fiber into a button so it won’t come undone. Do the same with the backside piece of string. Then, cut a new loop, bring it through that same hole, and continue on. It should make it look like your new piece of thread was actually a continuous strand. There should be no breaks in the stitching on the front-facing side of the leather.

“Cowboy” stitches, or just functional stitches, are 6 stitches per inch. Decorative stitches may be as tight as 12 stitches per inch. You’d want thinner thread for decorative stitching.

Leatherworking is something I want to get good at.

So, my plans with Dan’s chinks go like this:

Cut the leather patch to better fit the area needing repairs

Glue the patch to the torn leather without getting glue along my stitch line

Leave the old stitches intact and create a new line of stitches that tuck right against the tooled part of the chinks. (I don’t know what that part’s called, at least not yet!)

Brag to Dan about my handiwork

After I fix Dan’s chinks, I’d like to try to make a dog collar, belt, and little journal cover. Eventually, I’d like to get to the point where I can sell leather products and repair things for others. Doing so may be pretty darn lucrative, especially in a place where the two other leatherworkers only take on projects during the winter.

I’m trying to convince Les that teaching a leather workshop this February might be worth his time. I’d certainly come up and spend a week in his heated shop for something like that, no arm twisting required.